Automatic Gauge Control | Blown Film Extrusion

Reduce Film Thickness Variations by 50+%

The patented EGC system stands out among all other air ring based systems through the number of control zones, 132-244, depending on the air ring size.

This high number enables the system to address film thickness variations that other systems cannot.

The EGC incorporates the well known Addex air ring that assures the highest possible output.

The Air Ring The air ring is equipped with horizontally sliding teeth that adjust the air flow through the radially located vanes in the air ring’s plenum causing preferential cooling on the outside of the bubble. A circuit board inside the air ring converts the mapped thickness profile into instructions for the scanning actuator which slides "in" or "out" a multitude of fingers (132-244 depending on air ring size), as needed, to open or close the airflow channels (vanes).

The Mapper Processes the raw signal profile and the reversing or fully-rotating nip position and nip roll speed.

| Size | Diameter | Number of Air Inlets | Number of Control Zones 4"–8" 100–200 mm |

48" 1220 mm |

6 x 4"/102 mm | 90-144 8"–16" 200–400 mm |

56" 1423 mm |

6 x 4"/102 mm | 120-168 16"–24" 400–600 mm |

64" 1626 mm |

8 x 4"/102 mm | 168-216 24"–36" 600–900 mm |

76" 1931 mm |

10 x 4"/102 mm | 224-288 Larger ones are available upon request | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- The Live Ring (Carousel - left image): Located between the highest frostline and the collapsers.

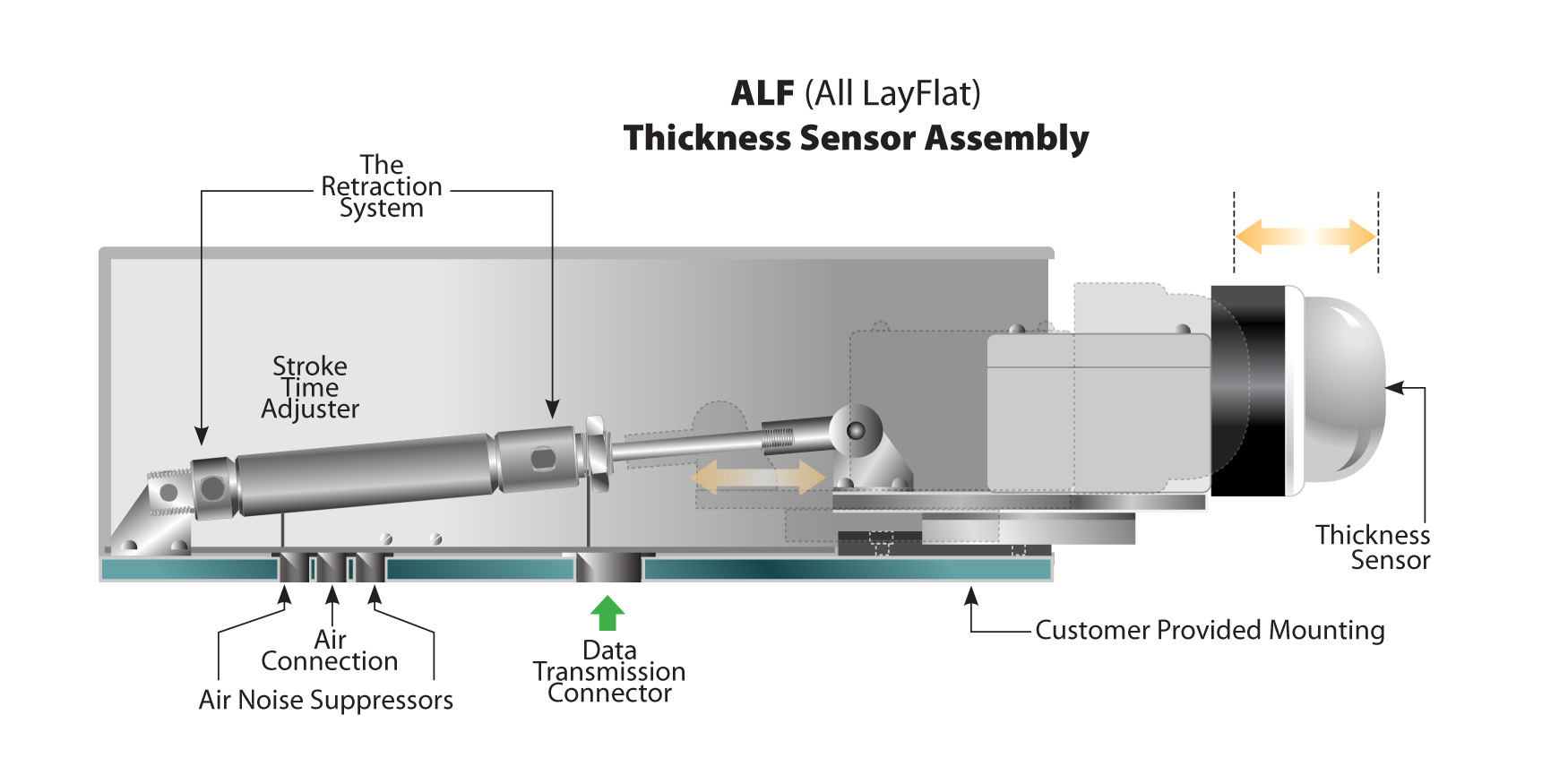

- ALF (AllLayFlat - right image): Located in the middle of the collapsing frame.

- Scanner: Located after the primary nip.

Thickness Sensor Options

- Capacitive (Standard)

- Air Cushioned Nuclear (Gamma Back - scatter)

- Air Cushioned Capacitive

- IR (ifrared) Identifies barrier layer thicknesses

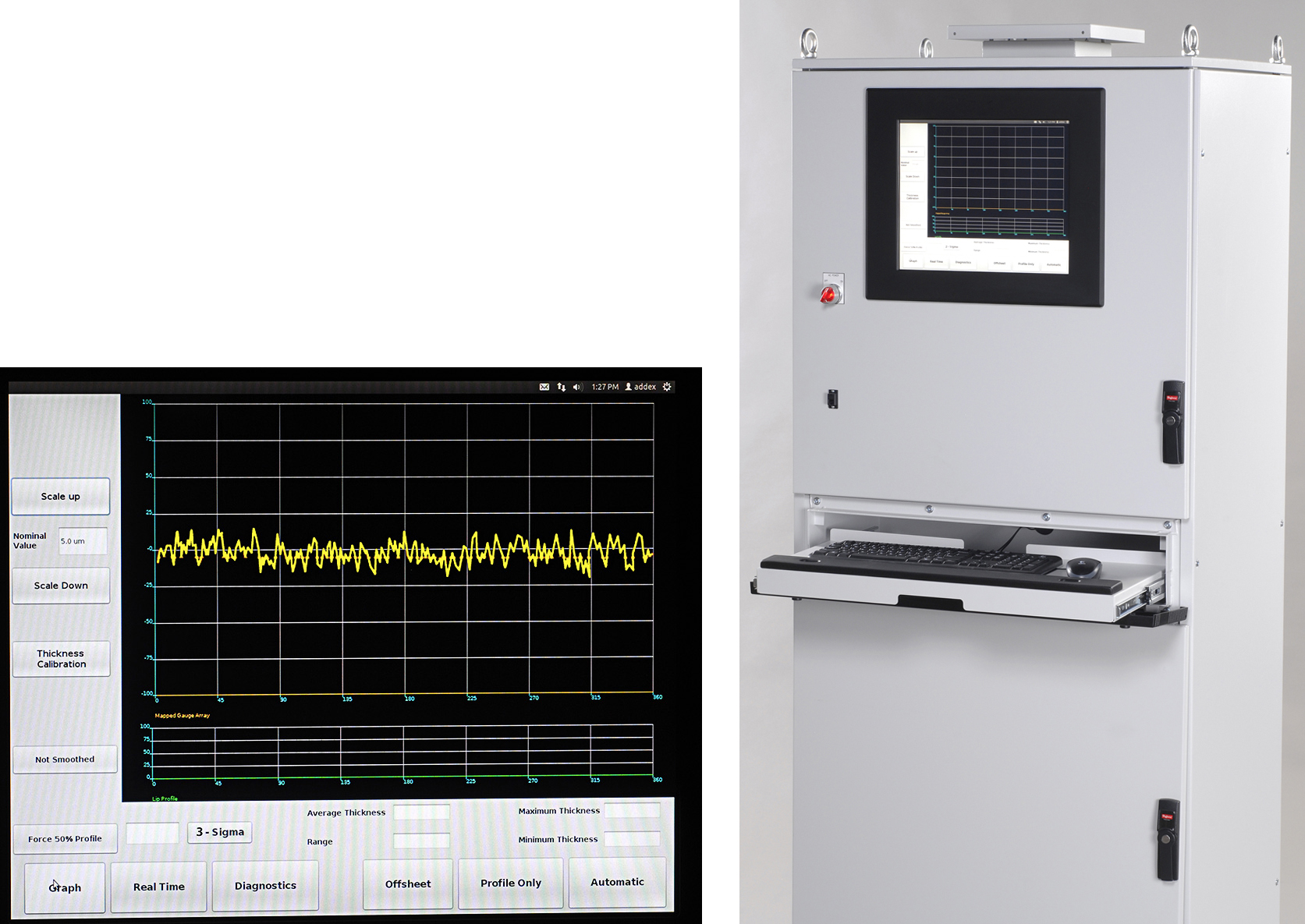

- Graphical User Interface Displays:

- control and air profiles

- trending and profile statistical analysis

| US | METRIC D" x 150 = CFM @ 80ºF & 25"H2O |

D mm x 10 = m3/h @ 27ºC & 6.2 KPa LEGEND: D"= Die diameter in inches D mm = Die diameter in mm CFM = Cubic feet per minute F = Degrees Fahrenheit C = Degrees Celsius |

|

|---|---|---|---|

Features

Features

- Film thickness variation is corrected by the automatic adjustment of the air flow through the air ring’s vanes.

- Air flow and air ring’s optimum cooling capacity is preserved regardless of the adjustments.

- High resolution of the control is assured by the multitude of control zones that can be moved to any "in" or "out" position within each vane.

- Ethernet and single power source connection.

Intensive Cooling-Enhanced Air Rings

All Addex air rings—LFR, MGC and EGC—are now available with intensive cooling-enhanced technology!

Addex has taken air ring technology to a new level by integrating intensive cooling technology directly into the dual-flow air ring design. The new intensive cooling air rings typically deliver 10%-15% or greater output and better bubble stability—over and beyond Addex’s already high performance, industry-standard dual-flow air ring design.

Addex has taken air ring technology to a new level by integrating intensive cooling technology directly into the dual-flow air ring design. The new intensive cooling air rings typically deliver 10%-15% or greater output and better bubble stability—over and beyond Addex’s already high performance, industry-standard dual-flow air ring design.

This newly adapted, patent-pending cooling technology replaces the standard lower lip with a single intensive cooling element on Addex’s dual-flow air ring system. The previous low-velocity lower lip is transformed into a high-velocity air stream, creating two primary locking points instead of just one, to significantly improve bubble stability. The intensive cooling enhanced air rings also include all of the secondary air collar locking points found with the original air ring design. The units are simple and operator friendly, allowing a broad range of processes, blow-up ratios, thicknesses, and materials with minimal adjustments.

The new intensive cooling-enhanced technology applies to all of Addex’s air ring products including automatic profile external gauge control (EGC), manual gauge control (MGC), and laminar flow (LFR) air rings.