Visitors caught a glimpse of the future on the Windmöller & Hölscher (W&H) booth at K 2019, as the machinery maker demonstrated the automatic stopping and restarting of a blown film line in suitably ‘filmic’ Hollywood style, and all in the space of around ten minutes.

The Turbostart control module was automatically stopping and starting a Varex II blown film line. Both processes demand a deep knowledge of the right steps and adjustments to be carried out in the correct order, but Turbostop and Turbostart enables the process to be broken down into seven steps.

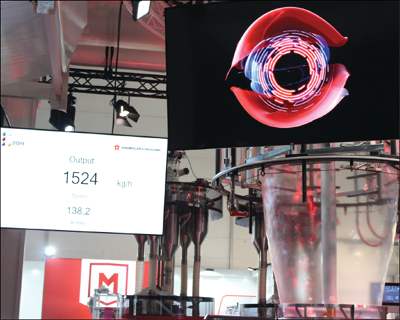

During timed demonstrations, visitors could watch the line stop before an operator had to intervene only minimally to get it going again. With Turbostart, preparation of the thread-up band and lowering of the air ring are done automatically, before an operator pulls out the melt and ties it to the thread-up band. Again, automation then takes over to stabilize the bubble. With upwards of 500 parameters to consider, the ability to handle process stability automatically is a considerable boon to operators.

The system also enhances operator safety through less knife usage during the start-up process. There is no longer a need to insert slitting knives in order to separate film or prevent air entrapment.

Restart takes under ten minutes rather than the traditional 30 minutes, and there is reduced waste, as it also uses less resin.

W&H’s latest Internet of Things (IoT) system for digitizing the value chain was also part of this live demonstration. Dubbed Ruby, it is an operating platform to collect and visualise data.

“Ruby delivers real time information and data sources from the whole value chain,” explained Torben Fischer, division manager for cast film at W&H. “Ruby is an operating system and can reflect future needs. The gain for extrusion is in the analytics. The more data you put in, the more knowledge you get out.

“Ruby allows the user to define where they keep the data and who they want to see it.”

The company also used the show to announce that it had entered into an exclusive license agreement with North American cooling ring specialist Addex for the development of a building block to use the Intensive Cooling (IC) technology.

The revised cooling system is a further development of W&H’s ARCTIS cooling ring family and was presented for its blown film lines at the show. The system is specifically designed for those applications where extra power is required. Difficult-to-use applications benefit from the increased process stability of the revised system.

“We analysed all the elements of the cooling system, reworked them and optimized them for high performance, right through to the complete redesign of individual components,” explained Martin Backmann, head of research & development for blown film at W&H.

Speaking about the addition of the high-performance cooling system, Dr Torsten Schmitz, head of the extrusion business at W&H, said that it allows other performance records to be broken on the Varex II line.

In fact, during the show W&H dramatically demonstrated just how hard it could push the system, by reaching a peak output of 1,558kg/hr on a 400 nozzle before the bubble burst.

Addex first introduced the patented Intensive Cooling air ring design at K 2016. It began as a stackable configuration of two to four cooling elements, which were fully enclosed and mounted between the die and the air ring. By causing air from each cooling element to flow in opposing directions and so creating a vacuum, bubble stability was greatly improved, which in turn led to massive output gains.

In fact, the output gains proved too great for the retrofit market to accommodate, so the company replaced the lower lips in an Addex air ring with just a single, aerodynamically-designed Intensive Cooling element. This change placed output at the ‘sweet spot’ for retrofits, delivering a guaranteed 10-15 per cent (or more) output increase that older lines could handle.

Addex licensed the original stackable design to other OEMs for use on new lines, while penetrating the retrofit market with these air rings. The company has sold more than 100 Intensive Cooling air rings into diverse applications from bag making, to lamination films, to barrier.

Phase 2 of Intensive Cooling development is now underway, with Addex examining the design of other components in the blown film process, such as the main air lip design, air collars and internal bubble cooling (IBC) – all to optimize total system performance in combination with Intensive Cooling.

Web: wuh-group.com